Building a model in Aspen consists of the following steps:

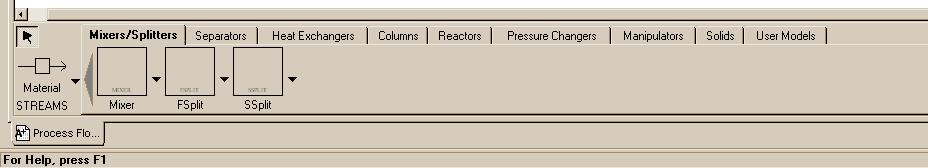

When creating the flow diagram, you may employ a variety of equipment. We have compiled a list of equipment icons which are commonly used in CENG 403 projects. These icons may be brought up and put on the flowsheet from the bottom of the main Aspen window. This is the way the bottom part of the screen looks when you first create a new blank window:

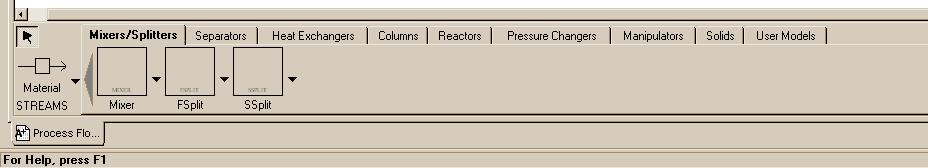

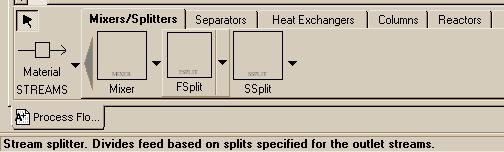

Note that there are nine different categories of units shown as "Tabs". The first category: Mixers/Splitters comes up as being selected when the window first opens, but you can select any of the others with the left button. Each of the categories then has several types of units shown as icons below the name of the category. The three types in the first category are the mixer and two types of splitters. The default icon for these is simply a box with the name shown below it. If you click on one of the icons, it will become lighter in color and you can then make a copy of it in the blank window by clicking at any position in the window. You can continue to add that same unit by additional clicks in the flowsheet space. For example clicking three times in the flowsheet after selecting the Mixer icon might produce:

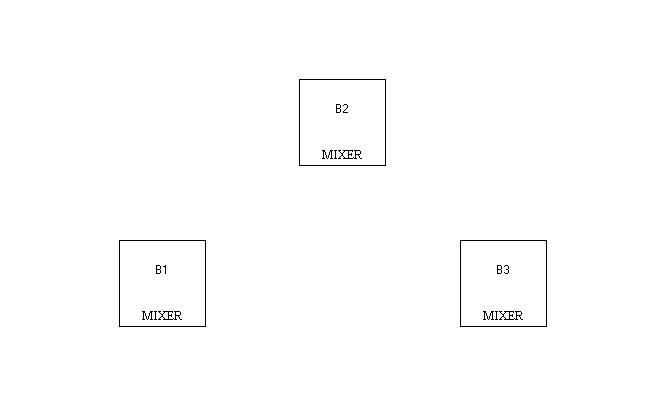

If you click on one of the icons it will be selected ( the corners will have colored squares on them and black squares will citcle the icon) and you can then do several things to it. Click the right button to bring up a menu that lists the operations and select among the one you want:

The most frequently used of the operations are: Delete, Rename, Rotate and Exchange Icon. If you select Exchange Icon, you will find there are lots of other ways to represent a mixer such as:

|

Mixer - Mixes streams together. FSplit - Divides feed based on splits specified for the outlet streams. SSplit - Divides feed based on splits specified for each substream that may be entering the splitter. For example, an entering stream may be a mixed solid and liquid in the form of a slurry. The solids in the inlet may wind up preferentially in of of the exit streams from the unit. |

If you want more information about the unit, place your cursor over the icon and (without clicking on it) hit the "F1" key. This should bring up a help window that will tell you more.

|

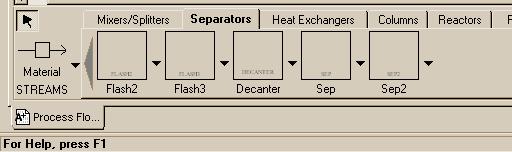

Flash2 - Two-outlet piece of equipment that allows you to model flash separations based on vapor-liquid equilibrium. Flash3 - Three outlet flash for systems that might produce a vapor and two liquid streams Decanter - Separator with two liquid outlet streams Sep & Sep2 - General separators of compounents in a stream |

|

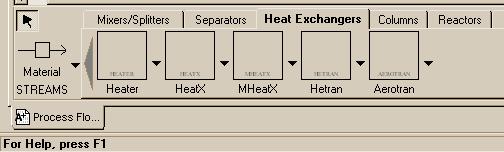

Heater - Extremely simple model of a heat exchanger. Basically allows you to determine the energy requirements of changing a stream's temperature. HeatX - Models a two-stream co-current or counter-current heat exchanger. |

|

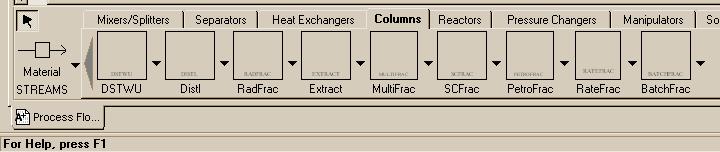

DSTWU - One of two primary models of a distillation column. Of the two, DSTWU is the simpler, allowing you to model a column based on shortcut methods when you do not know many of the parameters. RADFRAC - Aspen's other model for a distillation column. Rigorous and complex, this model should only be used when you are extensively familiar with the system you are attempting to model. |

|

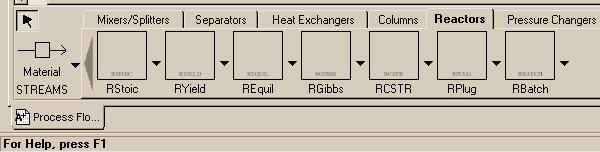

RStoic - Models a reactor for given stoichiometry and extents of all reactions REquil - Models a reactor with some specified set of reactions assumed to be at thermodynamic equilibrium RGibbs - Models a reactor with minimum Gibbs Free energy RCSTR - Models a Continuous flow Stirred Tank Reactor (CSTR). RPlug - Used to model plug flow reactors. RBatch - Model of a batch reactor. |

|

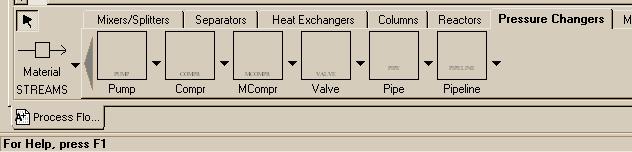

Pump - Used when you need to simulate a pump in a flowsheet for transporting liquids. Compr - Polytropic or isentropic compressor for gases. |