Introduction

Linear

cascades

Linear cascades are commonly used in

several mass transfer devices consisting of assemblies of individual units, or

stages. These stages are connected to ach

other in such a way that the material being processed has to pass, usually as

two streams moving counter-currently, through each stage in turn; therefore the

term cascade is used to describe them.

In each stage, they are brought into contact, mixed and then

separated. (McCabe, Smith,

Harriott). For simplifying purposes, the

stages are assumed to be ideal; that is, the leaving streams are assumed to be

in equilibrium, although in reality they are not. Although a stage can be represented in

several ways, for this example, each stage would be simulated as a binary

splitter, such as the one described in Example 23.1-2.

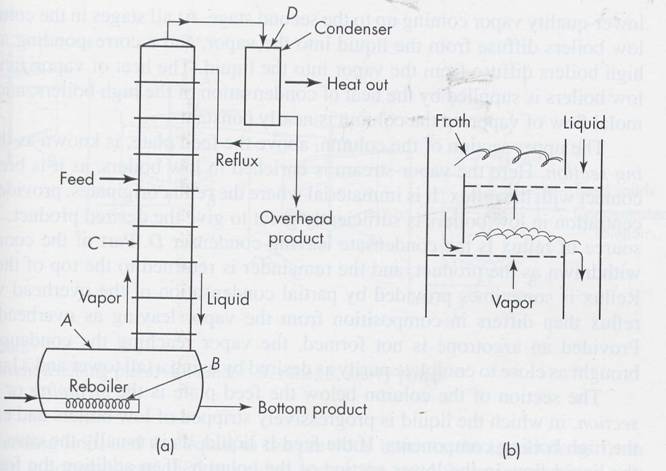

Linear cascades are used in a variety of

processes such as gas absorption and distillation, where the stages are

arranged in a vertical column (one on top of the other), or in leaching, where

the stages are basically a series of stirring tanks. The first type of arrangement, which is the

one described in Example 23.5-3, can be observed in Figure 1. Although a vertical column such as the one

described in this example can be used in distillation as well as in gas

absorption, there is usually no reflux (liquid obtained from the condenser that

is returned to the top of the column) in the latter one, therefore creating the

need of using several operating lines to describe the operation. Since I will be discussing total reflux, you

are encouraged to think of this example as a possible condition in which to

operate a distillation column. In fact,

batch distillation is run at total reflux.

Batch

distillation

In batch distillation, the idea is to use

vapor liquid equilibrium (VLE) to achieve a separation of a solution into its

more volatile and its liquid parts. To

do this, a mixture is feed into a still or into a reboiler and then passed

through a rectifying column, usually mounted on top of it (as in our example),

with reflux to increase the purity of the overhead product.

Figure

1: (a) Reboiler with fractionating column; (b) Detail of sieve plate (McCabe,

Smith, Harriott)