Home

Home

The hardest thing to learn in life is

which bridge to cross and which to burn.

David Russell

Day 4: Anion Exchange Chromatography

Assignments Due

- Draft of Introduction with References is

due at the beginning of lab. *Please do not staple pages; use

a paper clip.

- Protein Purification Reference: go to "Assignments" in

OWL-Space and follow the instructions.

Bring this information to the 4th day of lab.

- Materials and Methods (McMillan: pp.

61-66, 126-160 (3rd ed.); 80-83, 167-205 (4th ed.); 71-76 (5th ed.))

- Methods for measuring protein concentration (Scopes 2nd ed. pp. 278-283; 3rd ed. pp. 44-50)

- Study Guide (bring a copy of this to lab)

- OWL-Space BIOC 311 Resources (review before

Monday discussion)

- [Plagiarism]

- [Writing Resources]

- 144Errors_Handout.pdf

- 145Numbers_HandoutR.pdf

- Template for taking notes.pdf

- Model paper from "Protein Expression and Purification"

Preparation

- Plagiarism and Research

Paper overview

- Writing the Materials and Methods

- Anion exchange chromatography (set-up of system)

- Protein determination

- Protein purification tables

Overview of Experiment

Run ion exchange columns using a salt gradient to elute adenosine

deaminase. Complete all the measurements needed to complete

a purification table for your enzyme preparation including

activity measurements for all stored samples and the Q-cartridge

fractions. Determine protein concentrations for Q fractions.

Procedures

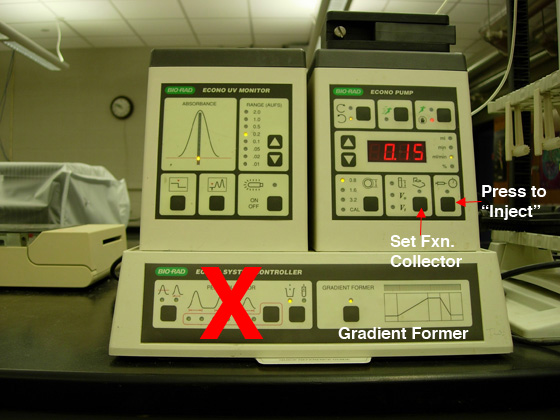

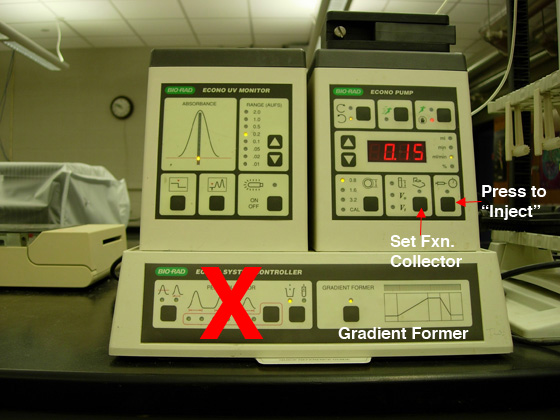

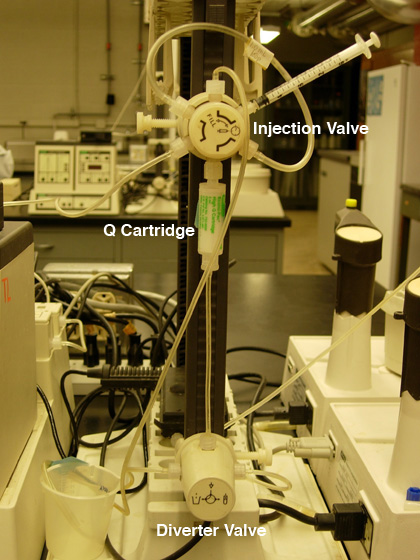

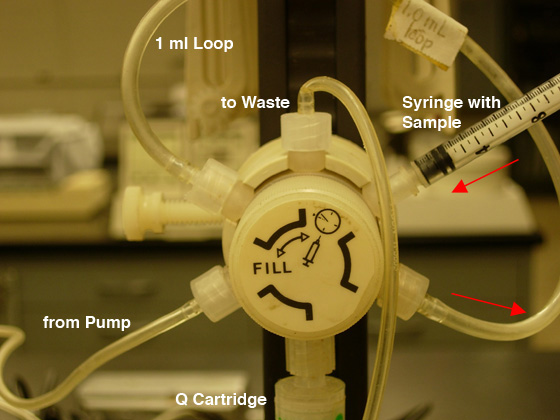

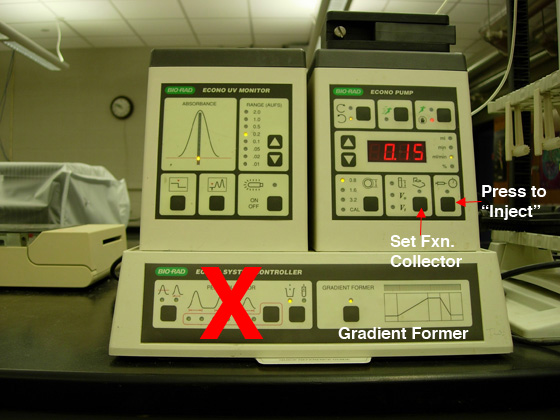

The chromatography systems have been plumbed for running the

ion exchange cartridge. All components of the station will

be used except for the "peak collection" option, marked with

the red "X" (see Fig. 1). Each team

will share an instrument. The same conditions should be used

for both native and recombinant preparations and the samples

will be run sequentially. Construct a 0.5 M salt buffer (250

ml is sufficient volume): add salt to your anion exchange buffer.

|

|

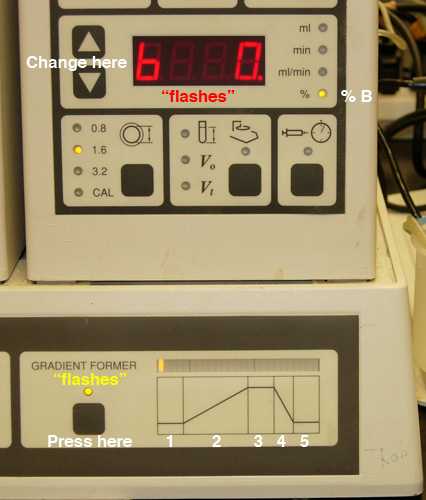

Fig. 1. A) Pump settings for anion exchange

chromatography. |

B) Q cartridge hook-up. |

Preparation of Sample

- Wearing gloves, rinse the outside of the dialysis tubing with RO water.

- Recover the residue from the dialysis tubing with a MINIMUM

of anion exchange buffer.

A total final volume of less than

1 ml is recommended. Achieve a more quantitative recovery by

rinsing the tubing with more than one addition of fresh buffer

(e.g., three rinses with 0.3 ml or two rinses with 0.5 ml are

better than one addition of 1 ml).

- Mix the recovered suspension

well to dissolve the residue.

- Centrifuge in a 1.5 ml tube for

5 minutes at maximum speed to pellet any insoluble material.

- Using a 1 ml syringe, filter the supernatant through a

0.45 µm

filter into

a clean 1.5 ml tube.

The sample is ready for loading onto the Q cartridge.

Caution: Do not shake to cause foaming while attempting

to dissolve the material. Foaming indicates the presence of

denatured protein that will act as a detergent to denature

even more protein.

Preparation of High-Salt Buffer

- Prepare 500 ml of 0.75 M salt in anion exchange buffer

= high-salt buffer

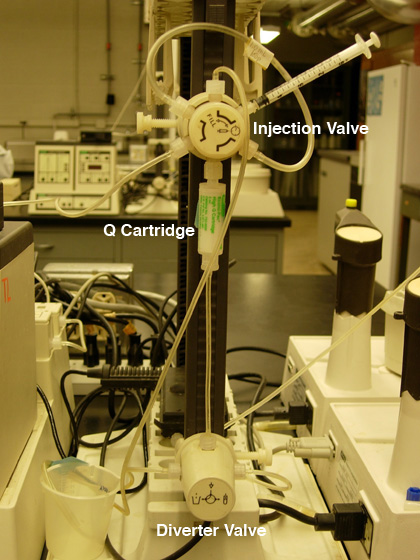

Q Cartridge Set-Up: Bio-Scale™ Mini Macro-Prep® High Q Cartridge,

5 ml (Bio-Rad Laboratories, Hercules, CA)

NOTE: Use ONE pump station per team and run columns sequentially. Use

ONLY the "slow-running man" when operating the pump

today (i.e., do NOT ever use the "fast-running man" =

purge).

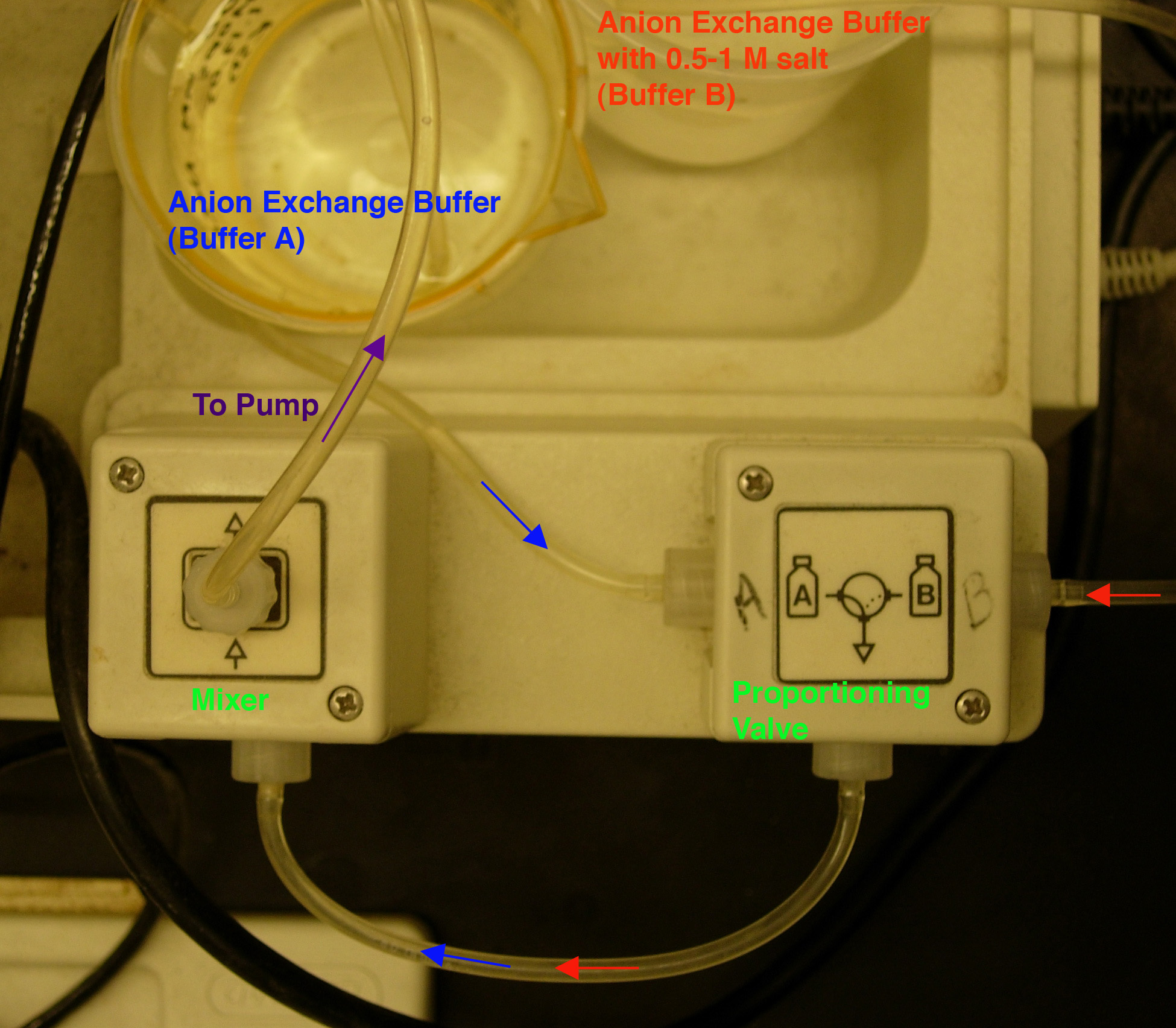

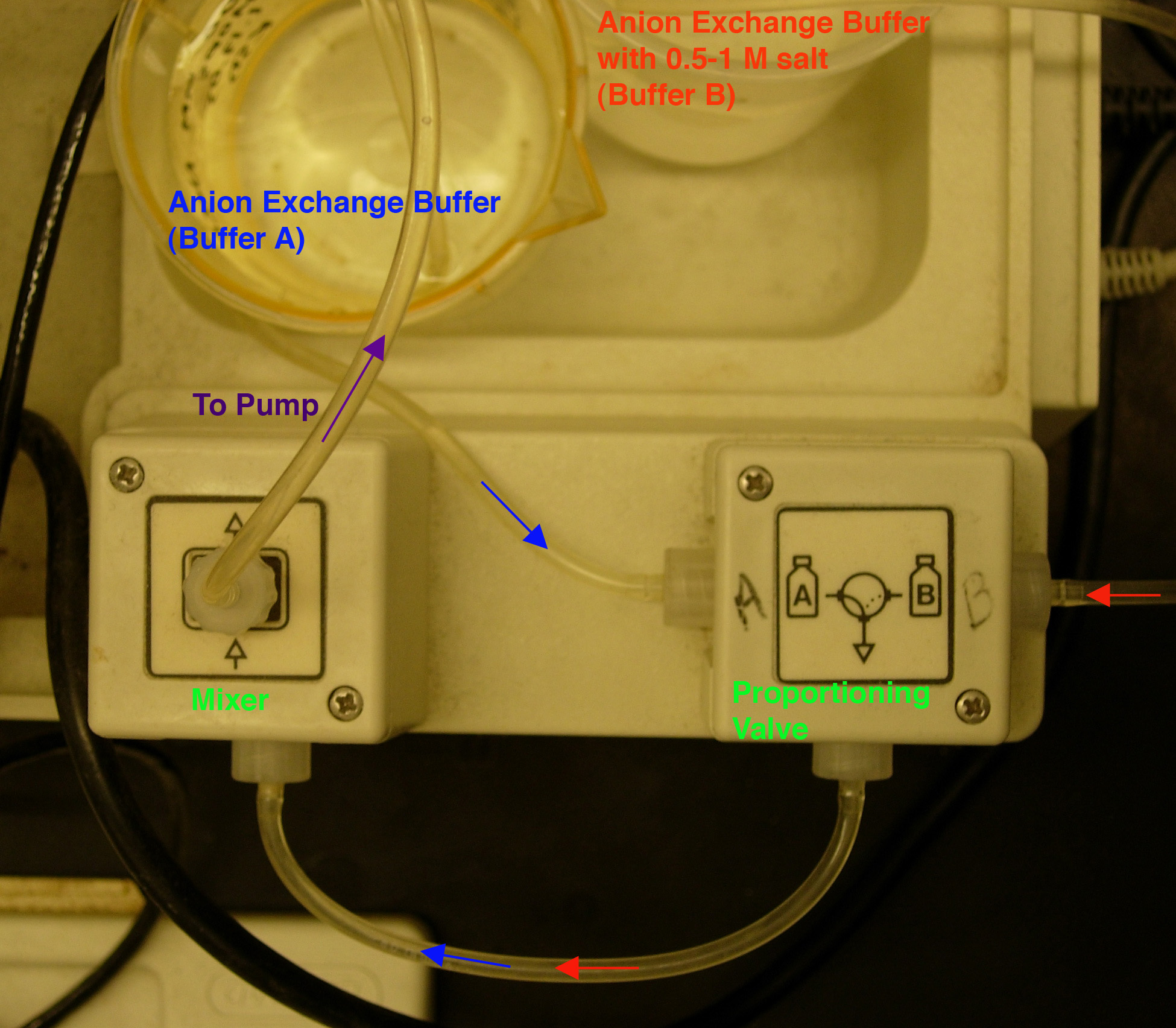

- Install low-salt (anion exchange buffer) and high-salt buffers

in the chromatography system (Fig.

2). Buffer "A" is

anion exchange buffer (loading buffer) and Buffer "B" is

anion exchange buffer plus 0.75 M salt (eluting buffer). NOTE:

the pump tubing diameter is 1.6 mm.

By DEFAULT, the pump pulls through the Buffer A line;

to switch between buffers A and B, press the "Gradient Former" button

while the pump is running.

Fig. 2. Buffer set-up.

- Set the flow rate to 6 ml/min.

- Disconnect the top of

the Q cartridge from

the system and flush the lines with both buffers (this

step will only take a few seconds).

- Reconnect the Q cartridge and at a flow rate of 6 ml/min

a) wash with Buffer B (eluting buffer) for 5 min.

b) wash with Buffer A (loading buffer) for 5 min.

The column is now equilibrated in your loading buffer.

c) Reduce the flow rate to that which will be used for the purification.

d) Between sample loadings, at 6 ml/min, wash with 0.75 M salt

buffer for 5 min followed by loading buffer for 5 min.

Remember to return to the desired flow rate before

loading the second sample.

e) After the second run, regenerate the cartridge by washing

with 0.75 M salt buffer for 5 min at 6 ml/min.

- Set the flow rate for your run; Bio-Rad recommends

2.5 ml/min for the 5 ml Q cartridges.

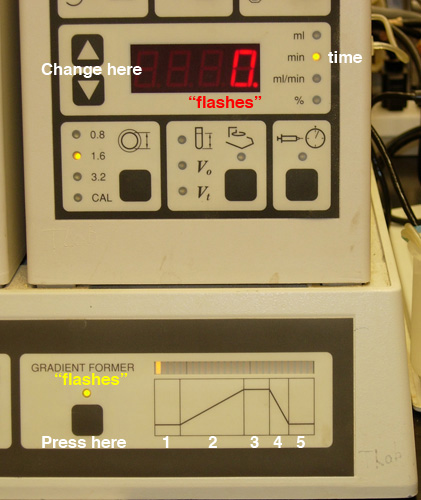

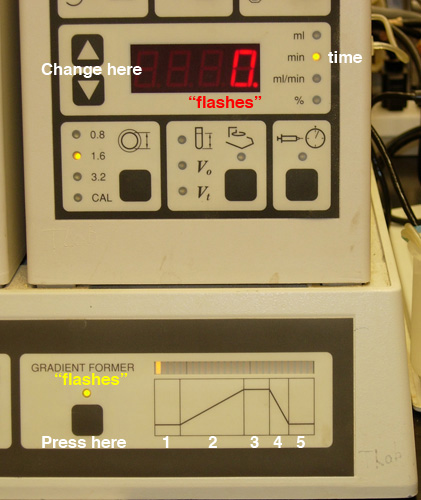

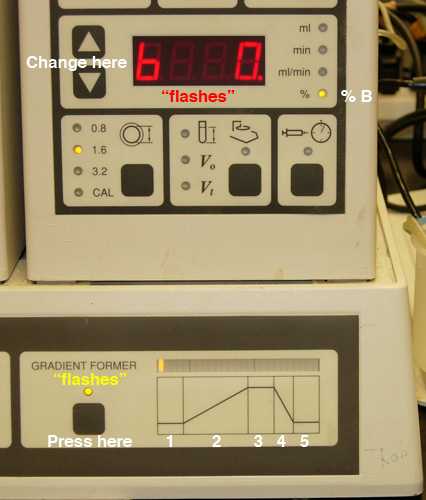

- Program a gradient of no more than 30 minutes TOTAL elapsed

time (Fig.

3).

|

|

Fig.

3. Setting the gradient: A) Selection of "time" for

a given step. |

B) Selection of "% b" (Buffer B) for a given step. |

- Set the fraction

volume ("test tube") to 3 ml using the

pump (*you do not need to set Vo, Vt, or # fractions) and

put 25 plastic tubes into the fraction collector carousel

NOTE: Make sure you see a "dashed, red line" on the fraction

collector LED (see Fig. 4).

Fig. 4. Appearance of the fraction collector when it's

controlled by the pump.

- Set the UV monitor: select 0.02 for RANGE;

ZERO the monitor as on day 3.

- Activate the pump (turn "on" using the slow running

man)

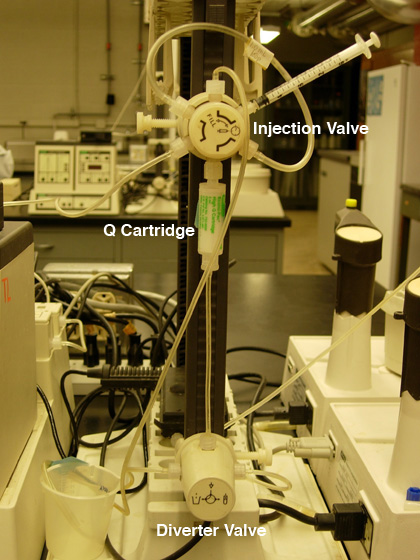

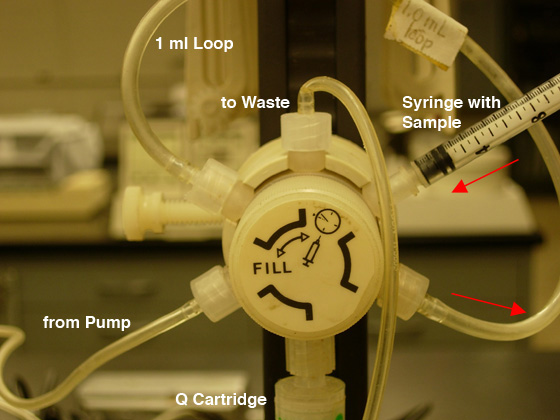

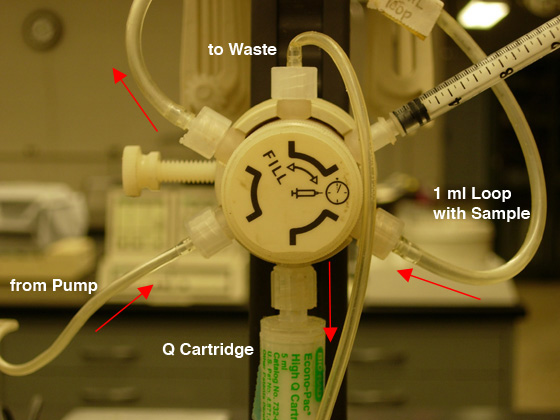

- Be certain the injection valve is in the "Fill" position (CCW) then

load your sample into the injection loop (maximum of 1.3 ml)

using the syringe (see Fig. 5A).

DO NOT REMOVE THE SYRINGE FROM THE PORT!!

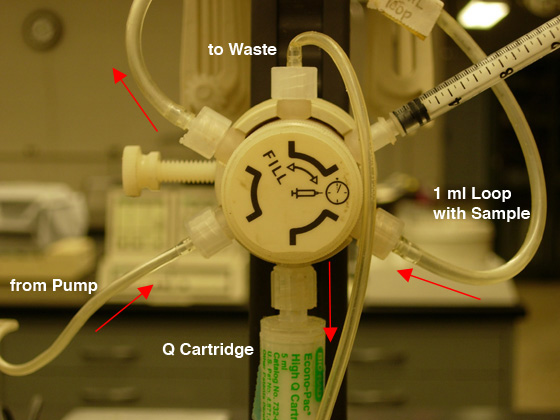

- Check that the fraction collector is ready and the chart

recorder is on; then move the injection valve to the "Inject" position (CW),

and push the blinking "Inject" button to

start the gradient (see Fig. 5B).

|

|

Fig.

5. Sample loading: A) FILL the LOOP (CCW position).

|

B) INJECT the COLUMN (CW position). |

Observe that the sample is being rinsed into the cartridge and that the fraction collector is started.

Monitor the progress through the first two or three tubes to be certain of function and alignment of the fraction collector.

- Use the Qualitative Spectrophometric Assay for ADA Activity (SAME as on Day 3) to find the ADA activity in your fractions.

*YOU MUST USE THE SPECTRONIC GENESYS 5 SPEC'S FOR THIS ASSAY.

**ASSAY ALL FRACTIONS!

- Combine the active fractions and obtain an A280

reading for the combined fraction as you did on Day 3;

this value will be used to determine protein concentration. What

buffer do you use to AUTO ZERO the spec?

SAVE YOUR PROTEIN SOLUTION!!

- Use the ADA activity spectrophotometric assay at

265 nm, as used on Day

1, to obtain QUANTITATIVE

assessment of the activity in EACH STEP of the purification

(NOTE: you do NOT need to use a CONTROL enzyme). Thaw the aliquots

from past steps and keep them on ice. Some samples may have

too much activity to measure even using only 1 µl.

Be prepared to dilute a small fraction of the aliquot to add

at least 10 µl to the assay for the activity

measurement; do NOT dilute ALL of the fraction aliquots. On

the other hand, some samples may have very little activity

in just 20 µl; you may add up to 100 µl of

fraction in the assay.

Obtain activity measurements for crude fraction,

P-60 fraction, and Q fraction for BOTH native and cloned sources:

- The measurements should be linear and in the range of

-0.02 to -0.06 ΔA/min

- CE must be diluted--first try 1:10 for NATIVE and 1:100 for CLONED

- Try undiluted P-60 and Q first; dilute only if necessary

- Remember to save the remainder of all

the UNDILUTED samples for gel and kinetic analyses;

DISCARD any diluted samples and leftover adenosine

NOTE: PERFORM THESE ASSAYS WHILE THE Q CARTRIDGES ARE RUNNING

- Add necessary components for stability (e.g., glycerol, DTT,

beta-mercaptoethanol, sucrose, EDTA) to the final purified

enzyme fraction.

NOTE: 0.5 M EDTA and 1 M DTT stock solutios

have been prepared for your use; you do not need to weigh out

these additives.

- Store final purified enzyme fraction in labeled 5 ml tubes

with screw caps at either 4°C or -20°C.

NOTE: set aside 50µl of your Q fraction for desalting

(see procedure below).

Desalting of Q Fraction for SDS-PAGE

All samples need to be in similar buffer prior to loading

the SDS-PAGE gel (in a subsequent lab).

The buffer composition of the Q fraction must be changed; the

sample will be desalted using small columns equilibrated in

Tris/glycine/SDS (25 mM Tris, pH 8.3, 192 mM glycine, 0.1%

SDS) running buffer.

Quick method for changing buffers of samples for SDS gels:

- Obtain an Ultrafree (0.22 µm) device for

each sample to be processed and insert the column into a 1.5

ml centrifuge tube.

- Using a disposable transfer pipet, fill the upper portion

of the Ultrafree device with a slurry of G-25 beads (about

400 µl).

- Pulse spin (hold the "SHORT" key on the microcentrifuge)

for ~15 seconds in the microfuge to remove excess water; discard

the flow-through (waste water).

- Add 100-200 µl of Tris/glycine/SDS (25 mM Tris, pH

8.3, 192 mM glycine, 0.1% SDS) running buffer to the gel material

and let stand for 1-2 minutes.

- Remove the excess buffer with a 15-20 second pulse spin.

- Carefully pipet 50 µl of your Q fraction on the gel

material and let stand 2-5 minutes at room temperature.

- Recover the sample in a clean 1.5 ml microcentrifuge

tube with

a 10 second pulse spin.

The sample will be in an acceptably desalted state.

- Store the sample at -20°C (*do NOT put "loose" tubes

in the freezer--use a screw-cap bottle).

- Rinse out the beads with RO water and RETURN the Ultrafree

device to the container.

Copyright, Acknowledgements,

and Intended Use

Created by B. Beason (bbeason@rice.edu), Rice University, 15 June 1999

Updated 23 May 2013

Home

Home